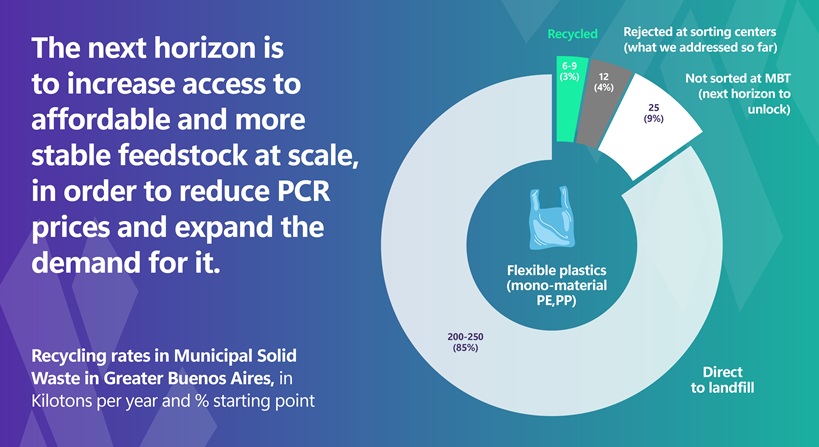

Flexible plastics make up a large share of municipal waste in Buenos Aires, yet only a small fraction is recycled today.

Our newly released report – developed through a two-year initiative led by Delterra in partnership with Dow and the Alliance to End Plastic Waste – is now live.

This project outlines how flexible plastics recycling can become both technically feasible and economically viable when the right incentives, operations and demand signals align.

Insights from our Webinar

These findings were also shared in our recent webinar, Unlocking Flexible Plastics Recycling in Latin America, where we discussed the results, lessons learned and opportunities for scale.

What we set out to solve

Across Greater Buenos Aires, flexible plastics represent roughly 40% of what households consume, but less than 3% is recycled. This is due to low source separation, inconsistent sorting, contamination and volatile demand for post-consumer resin. With no EPR regulation or recycled-content mandates, we set out to prove whether a market-driven model could overcome these barriers.

- Increased feedstock supply: By introducing a short-term, declining subsidy and training more than 500 waste workers, sorting centers doubled the volume of flexible plastics recovered. Importantly, the higher recovery rate remained even after the subsidy ended, thanks to strengthened trust and predictable offtake between cooperatives and recyclers.

- Strengthened demand for PCR: We worked closely with recyclers to improve extrusion processes, optimize blends of post-consumer and post-commercial materials and conduct routine quality control. With Dow’s support, recyclers gained access to new end markets such as garbage bags and construction materials. These combined efforts led to an 800% increase in monthly pellet production.

- Improved efficiency and scale: With expanded washing and extrusion capacity, recycler output rose from roughly 50 to 400–450 tons per month. Economies of scale brought down unit costs and enabled recyclers to remain profitable after the project ended – a rare achievement in post-consumer flexible plastics recycling without regulatory incentives.

Where we go from here

Our next phase of work focuses on expanding flexible plastics recycling in both Buenos Aires and São Paulo.

In Buenos Aires, our early mixed-waste recovery trials at the CEAMSE mechanical biological treatment (MBT) facility showed that flexible plastics can be separated and recycled into pellets suitable for lower-grade applications – but that automation is essential for economic viability at scale.

In São Paulo, we are beginning replication through partnerships with cooperatives and recyclers, leveraging the city’s semi-automated sorting plants and a more supportive policy landscape. Together, these efforts chart a shared direction: expanding demand, strengthening recycler competitiveness and unlocking new, reliably flowing feedstock sources across major Latin American cities.

A shared call to action

Scaling flexible plastics recycling will require collaboration across municipalities, cooperatives, recyclers, converters, industry buyers and policymakers. We welcome partners interested in expanding demand, piloting new applications or supporting replication in new geographies.

Together, we can accelerate circularity and climate progress across the Global South.